Thus far we’ve learned very basic ways of making our microcontroller interact with the world: GPIO mostly. But to build a folkrace robot we need a little bit more. Motors, specifically motors with variable speed would help. The most simple motor to use in this scenario is a DC motor, like the Pololu micro metal gearmotors.

Driving DC Motors, Theory

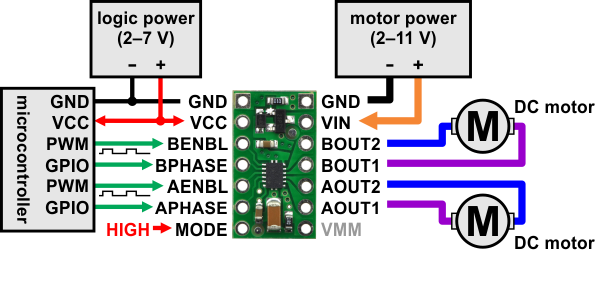

To drive a DC motor, we typically use a H-bridge based motor driver. In the case of the Robotics Club course, we are given a Pololu DRV8835 carrier board which contains the Texas Instruments DRV8835 dual H-bridge chip. “Dual” in this case means that one board can drive two motors, perfect for a simple differential-drive folkrace robot.

If we look at the “Using the motor driver” section in the “Description” of the carrier board’s page, we notice the following diagram:

The right side is dedicated to the motors, and the left side specifies the input signals expected from the microcontroller. We immediately notice that for this control scheme, the “phase-enabled mode”, we need to generate two PWM signals, alongside a few GPIO output signals.

The PWM Inputs

The PWM inputs of the driver control the speeds of the motors. For differential drive, we need 2 separate PWMs with their own duty cycle setting. This lets us set the speed of each motor individually. These PWM channels go into the AENBL and BENBL pins of the driver respectively.

The GPIO Inputs

The GPIO inputs control the direction of each motor. A simplified table is here:

| xPHASE | Direction |

|---|---|

| LOW | FORWARD |

| HIGH | BACKWARD |

Note: the specific direction will depend on which way the motor is connected, but the idea is illustrated clearly: put the phase high, motor goes one way; flip it low, motor goes the other way. This is all while keeping the PWM constant.

Breaking happens when the PWM duty cycle is set to 0, regardless of the phase direction.

The Mode Input

The mode input determines which control mode the driver uses. Since we use the phase-enabled mode, we need to pull the pin high. Do this by connecting the MODE input to the 3.3 V output of the STM32 Nucleo board.

Wiring

The driver has 5 inputs alongside various power and ground lines. We first need to find a good timer to generate 2 PWMs with. Timer 1 has 2 channel outputs right next to each other (PA8 and PA9) and doesn’t occupy the LED, so that’s fine. We can also choose the 2 GPIO right next to those two pins for the phase GPIOs: PA10 and PA11.

This gives us the final wiring table as follows:

| Driver | Nucleo | Other |

|---|---|---|

| GND | GND | - |

| VCC | 3V3 | - |

| BENBL | TIM1 CH2 (PA8) | - |

| BPHASE | OUT_M1_DIR (PA10) | - |

| AENBL | TIM1 CH1 (PA9) | - |

| APHASE | OUT_M2_DIR (PA11) | - |

| MODE | 3V3 | - |

| GND | - | Battery negative terminal |

| VIN | - | Battery positive terminal |

| BOUT2 | - | Motor 2 terminal |

| BOUT1 | - | Motor 2 terminal |

| AOUT2 | - | Motor 1 terminal |

| AOUT1 | - | Motor 1 terminal |

NB: Take extra care when powering the motor side. Use a lab power supply until you’re sure your connections are valid. Always check your wiring for shorts with a multimeter before you power things on.

Configuration

We have to configure 2 things:

- Timer 1 for PWM generation,

- GPIOs for controlling the direction.

Let’s start from the bottom and do GPIO configuration first:

And then the PWM generation. For the numbers, we’ll be going with a 40 kHz PWM signal again, primarily to minimize any kind of motor whine we might hear. So prescaler of 1, period of 99.

This is. Really it. Generate the code and let’s go into main.c!

The Code

So we’ll need a few functionalities with our code:

- Starting the motors.

- Setting the direction and speed of both motors.

- Stopping motors (optional).

The startup procedure is simple enough, if we remember the previous class: we start the timer, and we start both the PWM channels. In the code begin 2 section, we want to write this:

/* USER CODE BEGIN 2 */

HAL_TIM_Base_Start(&htim1);

HAL_TIM_PWM_Start(&htim1, TIM_CHANNEL_1);

HAL_TIM_PWM_Start(&htim1, TIM_CHANNEL_2);

/* USER CODE END 2 */

With this done, we now have to consider how we want to drive the motors.

Setting a single motor to drive in a given direction can be done as follows:

/* Infinite loop */

/* USER CODE BEGIN WHILE */

while (1)

{

int speed = 50;

__HAL_TIM_SET_COMPARE(&htim1, TIM_CHANNEL_1, speed);

HAL_GPIO_WritePin(OUT_M1_DIR_GPIO_Port, OUT_M1_DIR_Pin, GPIO_PIN_SET);

HAL_Delay(2500);

HAL_GPIO_WritePin(OUT_M1_DIR_GPIO_Port, OUT_M1_DIR_Pin, GPIO_PIN_RESET);

HAL_Delay(2500);

/* USER CODE END WHILE */

/* USER CODE BEGIN 3 */

}

/* USER CODE END 3 */

The code will set the first motor to proceed at 50% speed, and will alter its direction every 2.5 seconds. A similar part of the code could be written to modify the second motor as well.

However, our main loop is likely to be very busy with other things. So we’ll want to abstract

this logic a bit. In C, we can create our own functions. A classical function for a robot

like this is the motor_set(int speed_one, int speed_two) function. Which lets you set the

speed of both motors in one function call, but independently of one another.

We’ll write all of the following into user code begin 0, right before int main(void).

To define our own function, we first write the return type and the arguments of the function.

We already know the arguments: two speed variables, but do we want the function to return anything?

Not really, since it’s a setter function, ergo, the return type is void.

As such, we begin by writing this:

/* USER CODE BEGIN 0 */

void motor_set(int speed_one, int speed_two)

{

}

/* USER CODE END 0 */

Now, inside the function we need to write the logic for controlling the motors. Let’s focus on just one

motor. We’re passing in an int, which lets us use both positive and negative integers. It’s not too

hard to figure out what we can use this to our advantage: positive speed_one means motor goes forward

(GPIO is high), negative speed_one means motor goes backwards (GPIO is low). And in either case, we’ll

be writing the absolute value of the speed argument into the compare register using __HAL_TIM_SET_COMPARE().

So what would it look like? This:

/* USER CODE BEGIN 0 */

void motor_set(int speed_one, int speed_two)

{

if (speed_one > -1)

{

HAL_GPIO_WritePin(OUT_M1_DIR_GPIO_Port, OUT_M1_DIR_Pin, GPIO_PIN_SET);

__HAL_TIM_SET_COMPARE(&htim1, TIM_CHANNEL_1, speed_one);

}

else

{

HAL_GPIO_WritePin(OUT_M1_DIR_GPIO_Port, OUT_M1_DIR_Pin, GPIO_PIN_RESET);

__HAL_TIM_SET_COMPARE(&htim1, TIM_CHANNEL_1, -1 * speed_one); // (1)

}

}

/* USER CODE END 0 */

Notice the multiplication with -1 at comment (1). We can only write positive values into __HAL_TIM_SET_COMPARE(),

ergo we have to multiply speed_one with -1 to get a positive value corresponding to the desired speed.

Now, with this example written, we can simply add the same logic chain for motor 2:

/* USER CODE BEGIN 0 */

void motor_set(int speed_one, int speed_two)

{

if (speed_one > -1)

{

HAL_GPIO_WritePin(OUT_M1_DIR_GPIO_Port, OUT_M1_DIR_Pin, GPIO_PIN_SET);

__HAL_TIM_SET_COMPARE(&htim1, TIM_CHANNEL_1, speed_one);

}

else

{

HAL_GPIO_WritePin(OUT_M1_DIR_GPIO_Port, OUT_M1_DIR_Pin, GPIO_PIN_RESET);

__HAL_TIM_SET_COMPARE(&htim1, TIM_CHANNEL_1, -1 * speed_one);

}

if (speed_two > -1)

{

HAL_GPIO_WritePin(OUT_M2_DIR_GPIO_Port, OUT_M2_DIR_Pin, GPIO_PIN_SET);

__HAL_TIM_SET_COMPARE(&htim1, TIM_CHANNEL_2, speed_two);

}

else

{

HAL_GPIO_WritePin(OUT_M2_DIR_GPIO_Port, OUT_M2_DIR_Pin, GPIO_PIN_RESET);

__HAL_TIM_SET_COMPARE(&htim1, TIM_CHANNEL_2, -1 * speed_two);

}

}

/* USER CODE END 0 */

Make sure the inputs and channels all match in both sets. But the function is now done.

We can now use this in our main function like this:

/* Infinite loop */

/* USER CODE BEGIN WHILE */

while (1)

{

motor_set(50, -50);

HAL_Delay(1000);

motor_set(-50, 50);

HAL_Delay(1000);

/* USER CODE END WHILE */

/* USER CODE BEGIN 3 */

}

/* USER CODE END 3 */

And voila, we now have motor control!

Debugging

A final note about debugging.

If your motors are not moving at all, the first thing to do is to check the development board and driver side connections. Remove all motors and battery connectors from the motor side, and depower the entire system. Proceed to continuity check the pins on the driver to the nucleo development board, according to the connections table up to. A beep is good, no beep is bad.

If the continuity checks out but issues persist, we can also use a multimeter to debug the signals a bit. Again, disconnect everything from the motor side before proceeding. Put your multimeter into voltage mode, connect one probe to ground and use the other to probe signals.

Set your motors to drive at 50, 50 speed, for example. And then validate that:

- Both APHASE and BPHASE get a high signal.

- AENABLE and BENABLE should show somewhere about 3.3 / 2 volts, so 1.6 ~ 1.7 volts.

If one of those is missing, then recheck your connections and your code alongside the configuration. One of the values is not being written into the right place.

If that all works but the motors aren’t running, contact an instructor.

And finally, if your motors are going in the wrong direction, simply flip around their connectors.

Now, onto sensors!